Lulzbot Hexagon Hotend Build - Mini Workflow

Required Tools:

Torque wrench with 7mm crows foot adapter

18mm open end wrench

4.5mm open end wrench

1.5mm hex screwdriver

2mm hex screwdriver

Resbond 907TS Blue thread sealant

Required Parts:

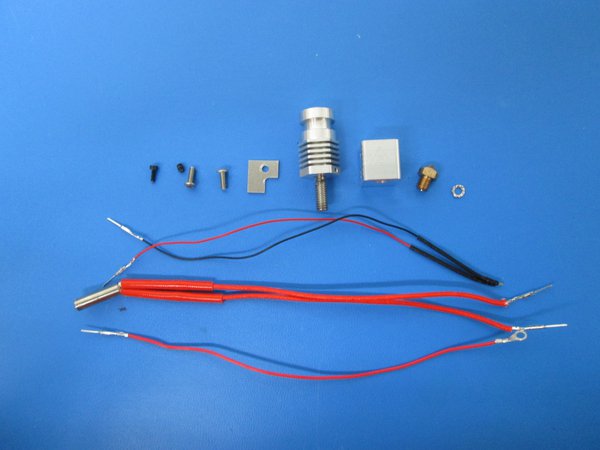

1 Hexagon thermistor with wires cut to 180mm and male pins crimped on ends

1 Hexagon heater cartridge with wires cut to 180mm and male pins crimped on ends

1 ground wire for nozzle, red 24AWG wire cut to 200mm with ground lug on one end and male pin on other

1 Hexagon heater block

1 Hexagon heat sink

1 0.5mm Hexagon nozzle (should say 5 on side)

1 thermistor retention plate

1 M3x4mm set screw

1 M2x6 SCHS

1 star lock washer

2 M3x8 stainless steel button head screws

- Have all the required parts?

If the nozzle came installed in the heater block, remove it.

Make sure that the nozzle says 5 on the side (0.50mm nozzle)

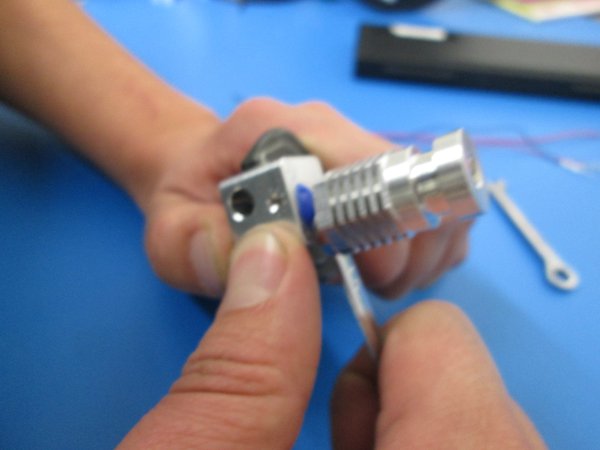

With the heatsink out of the heater block, install nozzle using a 7mm torque wrench and holding the heater block with a 18mm wrench.

Tighten to 30 in*lbs. .

- Next

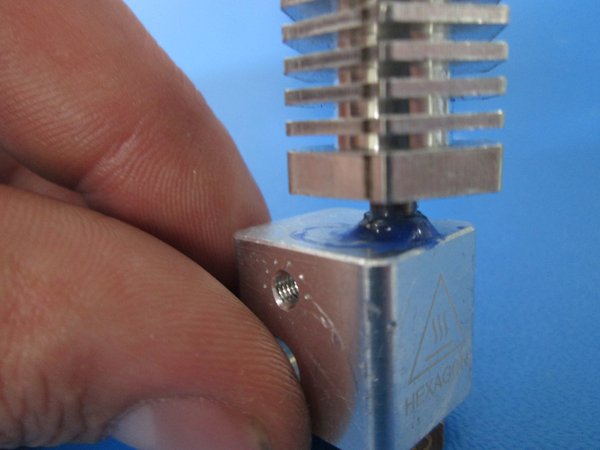

Shake the bottle of threadlock well to ensure it is well mixed.

Apply a generous coating of high temperature threadlock to the threaded portion of the heatsink, except for the last 2 threads as shown. This will ensure a good seal and that no locktight makes it's way down to the nozzle.

Install in the heater block tightly using a 4.5mm wrench and holding the heater block with a 18mm wrench.

There will be a significant amount of thread-lock on the top of the extruder block. Wipe off any that drips over the side, but leave the thread-lock around the heat-sink extension as a visual indication that there is thread lock on the threads.

Before the threadlock compound sets (within 5 minutes), rotate the heat-sink so that one of the points of the heat-sink faces the front and the set screw hole is somewhere in the back.

Lock the threaded extension into the heatsink using an M2x6 SCHS with a small amount of high temperature thread lock.

- Is there threadlock around the heatsink extension, but not running down the sides of the heaterblock?

- Is the M2x6 screw facing towards the back side of the heater block?

Take thermistor and pull back both pieces of the black shielding 1/2”

Make sure that the inner clear plastic tubing is all the way down to the bead of the thermistor

Slide ONE of the pieces of black shielding down to the bead of the thermistor and insert into the heater block, making sure that the shielding doesn't slide up from the bead of the thermistor.

- next

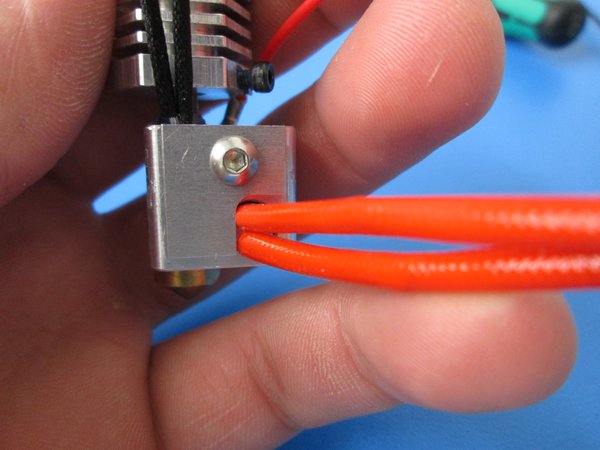

while holding the thermistor in place, slide the heater cartridge into the heater block so that the wires are coming out of the same face as the thermistor.

Secure heater cartridge and thermistor into the side of the heat block with a retention plate and an M3x6 BHCS.

Make sure that both leads of the thermistor are in the channel in the side of the heater block and not pinched against the flat face. One of the 2 black shield bits should be secured by the retention plate, the other should rest flush with the top of it.

Be sure that the retention plate is tightened seated completely flush against the block

Make sure that the front edge of the plate is parallel to the front face of the heater block.

Make sure that the retention plate is covering part of the heater cartridge, and that the wires are aligned vertically so that neither of the leads are touching the metal plate.

- Is the retention plate aligned to the top edge of the heater block?

- Is the retention plate covering part of the heater cartridge, but not touching either of the wires?

Pull heater cartridge up against the retention plate

Make sure that the wires are aligned vertically and that neither of the wires are close to touching the retention plate

Lock into place with am M3x6 set screw from the rear of the heater cartridge (no need for locktight here)

- Are the wires aligned so that neither is close to touching the retention plate?

- Is the heater cartridge pulled all the way up to the retention plate?

- Is there visible threadlock on top of the heater block, but not running down the sides

- Is the retention plate flush against the heater block?

- Is the heater cartridge pulled up against the retention plate?

- Are neither of the heater wires touching the retention plate?

- Is the heatsink screw facing towards the back side of the heater block?